NATURAL SPRAY CORK

Ecork natural spray cork, is a 100% ecological product that offers protection to different surfaces of all types of materials. Ecork material can be projected onto an infinity of surfaces such as: exposed concrete, ceramics, aluminum, glass, fibers, asphalt sheets, steel, fiber cement, polycarbonate, plaster, plasterboard, agglomerated materials, wood, pvc and enameled surfaces, among others. The projected cork can be obtained to solve any problem related to: dampness, waterproofing, acoustic insulation, slippery surfaces, fireproofing, and encapsulation of asbestos or bacterial infestation. In addition to all its technical qualities, it is an aesthetic material useful to decorating or embellishing any of the before mentioned surfaces. The projected cork can also be used as an insulation using it as an intermediate material between two other building materials. With the application of projected cork, definitive solutions can be obtained to solve any problem related to: dampness, waterproofing, acoustic insulation, slippery surfaces, fireproofing, and encapsulation of asbestos or bacterial infestation. In addition to all its technical qualities, it is an aesthetic material useful to decorating or embellishing any of the before mentioned surfaces.

Also, on top the projected cork any decorative paint for interiors or exteriors use can be applied (except our new construction system which needs our formulated colorants, to allow our cork to breath. Our new system doesn’t need water channels behind substrates).

Exterior Wall Finishes

Residential Exterior Finish

Projected Ecork is an excellent exterior wall finish, that can be applied over brick, cinder block, existing stucco/dryvit, and any other OSB systems.

If you haven’t yet heard of cork spray and its amazing properties, then read on! Eagle Ecork Industrial is proud to be at the forefront of manufacturing and distributing this wonder material that can be used on the interior and exterior of your home or building. If you’re tired of repainting your property and ready to save on your energy bills, then cork spray should be your next investment. Here are ten ways that our product, “Ecork ”, is better than any paint on the market! .

1. COVERS ANY SURFACE WITH EASE

Our goal at Eagle Ecork Industrial is to provide innovative and environmentally friendly coating systems for industrial, commercial, and residential use. Our products need to be durable as well as flexible enough to cover any and all surfaces. Unlike paint, our Projected Natural Cork adheres to any surface you can think of: wood, siding, aluminum, vinyl, steel, stucco—the list goes on and on! New construction, as well as older homes and buildings in need of a face-lift, can benefit from applied cork.

2. FLEXIBILITY: NO CRACKING OR FLAKING

ECork along with its other qualities, is naturally flexible and durable because of its cell structure. Under a microscope, cork has a honeycomb-like structure that traps air in its pockets—cork is 80-90% air. It’s this structure and the air trapped inside that allows the cork to be flexible and elastic without expanding and contracting with the elements. Where paint will crack and flake when exposed to the elements, cork spray will bend and move with the structure while maintaining structural integrity and therefore not crack under pressure.

3. NON-TOXIC AND VOC FREE

Though lead paint is a thing of the past in the US, there are still other toxic chemicals used to coat the buildings you interact with every day. Not with cork spray! Eagle’s Ecork is a water-based solution and can be applied to the outside or inside of a structure without face coverings. This all-natural polymer also contains no harmful organic compounds either, making it safe for your office, factory, and playroom.

Residential Exterior Finish

4. LOW MAINTENANCE AND DURABLE

One aspect that may deter you from investing in cork spray is the cost per square foot. However, we at Eagle Industrial urge you to compare the long-term costs of using cork spray to paint: over time, cork spray is the less expensive product. The color of cork spray fades ten times slower than paint and because it’s resistant to cracking and flaking, you may not need to reapply for years.

5. TOUGH ON MOLD

Resistance to mold and mildew is another naturally occurring feature of cork that will protect your home or building. Along with keeping out harmful allergens, this feature also helps keep the maintenance on your cork covered spaces to a minimum.

6. WATER PROOF

Though we’ve discussed the flexibility of cork because it’s made of 80-90% air, that doesn’t mean it lets anything in! Cork Spray is excellent for sealing your home from water damage while also being a breathable product. The impermeability to water is also natural to cork, which means when you’re spraying your basement, ceiling, or outdoor structure, you’re using a non-toxic method while keeping the water out.

Commercial Application

7. WOW-WORTHY INSULATION

Cork Spray’s number one selling point is its natural ability to insulate. With Eagle Industrial’s Spray Cork you can forget about tearing up old structures to add insulation—just spray and lock in your climate-control while keeping unwanted temperatures out! Whether it be your living room or your office you’ll be saving money on energy bills while being able to heat and cool your space to the temperature you want.

8. SOUND DAMPING WONDER

The honeycomb structure of cork does it again with its ability to dampen sound. By coating one side of a wall, cork spray can reduce noise by 9 decibels. Cork by itself has been part of soundproofing recording studios for years and now with cork spray you’re able to reduce the din of your industrial building or chatty coworkers.

9. FLAME RETARDANT

The last but certainly not least of cork’s incredible properties is that it’s naturally fire retardant. This built-in safety feature is excellent for residential, commercial, and industrial purposes alike—definitely not something paint can boast!

10. CLEAN AND GREEN

Finally, one of the best reasons to incorporate Eagle’s Ecork into your design is that cork is a sustainable resource. Rather than getting cut down to harvest what is needed, cork trees are stripped of their bark and then left alone to maintain the local ecosystem. During this time of regrowth, cork trees eat up three to five times more carbon dioxide than other trees, and cork forests are one of the biggest reducers in greenhouses gases which contribute to climate change.

PROPERTIES:

▪︎ Waterproof, yet breathable

▪︎ Fire retardant (class B)

▪︎ Acoustical insulator

▪︎ Flexible

▪︎ Totally green product

▪︎ Stops condensation

▪︎ Most durable coating in the industry

▪︎ Mold/mildew resistant.

▪︎ Cork doesn't rot.

▪︎15 year manufacturers warranty.

▪︎ Withstands wind and water speeds over 250 mph. Category 5 hurricanes wind speeds start at 150 mph. Highest hurricane wind speeds recorded in USA, (190 mph)

▪︎ Termites won't eat cork and seals building structure, so insects can not migrate into structure.

▪︎ Hail proof. We've tested with a baseball size rock that weighed 12oz. and didn't penetrate or mark the Spray cork.

Insulation, Exterior Wall Finish , Roofing

Get Corked!!

What is projected “Ecork”

The product is a Projected Cork coating that is mixed 80% cork granules in a Polyacrylate Resin Polymer base.

Each cork cell is a 14 sided polyhedron filled with air, with an extremely strong membrane that is waterproof and air tight!!! The air volume of cork is around 89%, which allows for both acoustic and thermal insulation barrier. Cork is a natural impermeable , and contains an almost magical chemical which renders it impermeable to liquids and gases. This chemical is a fatty acid and a heavy organic alcohol called “Suberin” , which also does not rot or degrade. This chemical also resists Mold and Mildew.

Cork is the cortex of the Mediterranean cork oak “Quercus suber”, growing in the south of Europe and the north of the African coast. It is cultivated mainly in Portugal, Spain and Algeria.Cork extraction is made by withdrawing cork oak cortex, where the material is located. Once cortex is withdrawn, the tree is “at rest”, and nine years later the extracting process will be renewed.

Cork oak is a strong tree which can reach up to 20 or 25m high. Its cortex is suberized, that is to say, composed by cork, being relatively soft and spongy, very light-weighted and with deep cracks. Its cortex protects the tree from injuries, sicknesses and insects. It is a death tree part which protects the living one, most of all to survive drought (protecting internal tissues from water losses) and fires. When there is a fire, the internal cork side closes due to the heat and avoids oxygen entry and therefore combustion, protecting the tree internal parts, which enables it to regrow anew the next season.

“Ecork” can be applied several ways. The most common application process is through a Texture Spray Hopper or a Texture Spray Machine. It can also troweled on or rolled on with a roller .

Harvesting Process

The harvesting and production of cork is not only sustainable, but it also serves to provide employment and economic purpose for many communities. Cork harvesting is an ancient tradition, using the same method for thousands of years. It is done by hand when a skilled cork harvester splits off the bark of a cork oak tree without damaging the rest of the tree. Each tree can live between 150 and 250 years, and is harvested every nine years – at least 15 times during its life. No other tree can support and flourish from this process, and cork tree harvesting actually improves the tree’s health and vigor. Furthermore, more than 100,000 individuals in the Western Mediterranean and Northern Africa regions depend on the cork industry for their livelihood.

After harvesting, the removed bark is dried in the sun, and handled differently depending on its use. Expanded Insulation Cork Board is produced from the natural cork granules which are steam-heated, causing the cork to expand. This activates suberin, a natural binder, thus requiring no added binders or chemicals during the production of insulation cork. Facade Cork is made in the same way, though utilizes different, and slightly superior, parts of the cork product for a smooth and more attractive appearance. Throughout the production process of both products, absolutely nothing is wasted. All waste is returned to the production process, making cork harvesting and production one of the most sustainable business practices on the planet.

Sprayed Cork applied to Garage Door

Amazing Thermal Insulation Benefits

Thermal Insulation Properties

First off “ECork” qualifies in nature as a thermal insulation material

A thermal insulation material is a material used in building and industry, characterized by its high thermal resistance. It sets a barrier to avoid heat transfer between two means which naturally would tend to balance its temperatures.

In general, all those materials offer resistance to heat transfer, but to be considered as a thermal insulation material its thermal conductivity coefficient (λ) is to be under 0.10 W/m²·K (K rating) measured at 23°C.

Thermal insulation materials with thermal conductivity of < 0.10 W/m²·K measured at 23°C. are called specific thermal insulation materials. Granulated cork particles have a K rating of 0.035 W/m²·K.

Before Applying Cork

Properties and thermal insulators characteristics

There are plenty of insulation materials on the market, but with differences among them. Their main characteristic is the thermal conductivity (λ) which differentiate one insulation material from another.

United States Building states that products for walls and blind spaces on façades are defined by the following hygrometric conditions:

Thermal conductivity

Thermal conductivity is a physical property which measures the insulation capacity of a material. The lower the rate, the more ability to reduce the rate of heat flow. It is an inherent property of the material, it does not have a fix value, because it depends on different factors such as temperature, density, humidity and the ageing process of the material.

Water vapour resistance factor μ.

It has to be taken into account especially in those insulation projects which aim to preserve a cold surface. If the insulation enables the air humidity to be in contact with the cold surface, there will be condensation and it will make the insulation material wet, generating insulation capacity losses, wet surfaces and even hygienical problems and molds.

Density ρ (kg/m3)

The volumetric mass density of a substance is its mass per unit volume.

Specific heat cp (J/kg.K)

It is the energy which results in an increase in temperature and proceeds to the transformation of other energies.

After Applying COrk

Ideal thermal insulation

Acknowledging the fact. Air is the key to every insulation project.

Water as a main heat conductor destroys the insulation value of any material.

Water is enemy number one of any insulating system. The problem lies in water in its natural status as water steam, that is to say, humidity. Steam is a constant condition in our atmosphere and therefore it will reach by any mean through the air.

Humidity, or water steam, is the worst foe to ideal thermal insulation.

Attic simulated insulation test

Hot air absorbs humidity

Dew point” is the temperature when the RH is of 100%. In this case air is not able to hold water and it starts to fall, first in tiny drops known as “dew” and, afterwards, as fog (it happens when there is a sharp fall on temperatures, when there is a lot of humidity in the environment).

When relative humidity (RH) is zero, it can absorb all the water, but when it is 100%, it is unable to absorb even an extra drop.

The higher the air temperature, the bigger the capacity to retain humidity. It is due to the ability of hot air to absorb steam. When air is heated it expands and makes “room” for more water molecules, so air is able to “absorb” more water (like a sponge). This process is known as “relative humidity”.

Temperature difference is in fact a pressure difference. Nature tends to balance this condition. Cold air is heavier than hot air. When the door of a cold room opens, cold heavy air slips from the lower part meanwhile hot air circulates through the upper part.

Hot air which contains steam comes into contact with cold surfaces and immediately it loses its ability to host humidity.

It leads to condensation: humidity is laid over the surface and insulation is exposed to its disastrous effects.

Taking into account the previous explanation, the ideal insulation would be one with the maximum gas content, air for instance, encapsulated and without the possibility of circulating.

These insulation principles have been widespread for a long time, but they have not been definitively assimilated until very recently.

The only conclusion to be reached out of these facts is that perfect insulation is to incorporate two unique characteristics:

They are: It must incorporate the biggest amount of standstill air within the smallest room.

and, It must be able to tolerate water intrusion by absorption.

There is only one substance that can meet both requirements and that is projected "Ecork''

Commercial Application

Finish Over Metal Siding

Commercial Application

Close Up—-Exterior as Stucco Alternative

Close Up Finish over Brick

Projected Spray Cork Uses

THERMAL INSULATION

First off ECOrk qualifies in nature as a thermal insulation material

A thermal insulation material is a material used in building and industry, characterized by its high thermal resistance. It sets a barrier to avoid heat transfer between two means which naturally would tend to balance its temperatures.

In general, all those materials offer resistance to heat transfer, but to be considered as a thermal insulation material its thermal conductivity coefficient (λ) is to be under 0.10 W/m²·K (K rating) measured at 23°C.

Thermal insulation materials with thermal conductivity of < 0.10 W/m²·K measured at 23°C. are called specific thermal insulation materials. Granulated cork particles have a K rating of 0.035 W/m²·K.

EXTERIOR WALL FINISH

Sprayed “ECOrk ” can be applied to a number of exterior finishes. I can be used over brick, cinder block, cement, wood, hardi plank, any OSB substrate, and is a an excellent alternative to the very popular stucco finishes used in construction everywhere. The benefits of “ECOrk” as an exterior finish include, thermal insulation, water proof and water resistance qualities, mold and mildew resistant, and also a professional quality finish.

It’s mechanical properties and water resistance reduce the formation of cracks, it stands out for it’s elasticity , high resistance to atmospheric agents and excellent adhesion to supports like concrete, plaster, brick and many other substrates.

It has gained popularity as a construction alternative to exterior stucco, and in many ways far superior to stucco in waterproofing exterior walls, but yet still breathable.

And don’t forget all these qualities are from an application thickness of only 3 millimeters.

WATER PROOFING

The water proofing and water resistance qualities of “ECOrk” are phenomenal. Laboratory test indicate that the natural qualities of cork mixed with a Polyacrylate Resin Polymer in an aqueous emulsion provide significant water proof and resistance characteristics on any surface applied.

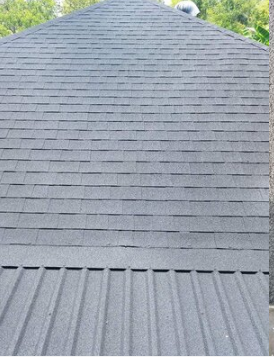

Roof Finish Systems

Roof Application

Roof Finish Application

One of the biggest and most important investments of your residential, or commercial structure, is your roof. Never worry about hail, or wind damage again, with “Ecork” Spray Cork. Super flexible, Waterproof and it Insulates. Saves 50%-65% on utilities. Bigger savings than solar systems and returns your investment faster.

The cork can be applied over flat roofs, shingle roofs and even metal panel roofs.

Roofs are costly parts of any building design. Having to replace one due to rust damage or missing shingles is a frustrating additional line item in any budget. Ecork:

Coats potential micro-cracks in roofs

Protects against water damage

Creates a waterproof seal that prevents rust.

This layer of cork and resin also insulates the building, keeping the costly HVAC inside—where it belongs! Long-term, this saves money for the operator. It's easier to keep a roof in excellent condition with the addition of a layer of cork spray.

House Roof Transformation

Before Applying cork on Asphalt Shingle Roof

After applying cork on Asphalt Shingle Roof

FIRE RETARDANT

On of the most fascinating qualities of cork is it’s fire retardant/Resistant qualities, which has been given a Class B fire rating in the construction industry . Lab tests have confirmed that cork will not burn construction component. Cork is and Non combustible does not propagate flames nor does it release incandescent particles.

ROOFS

Sprayed “ECOrk” can be applied over many types of roof structures, from conventional asphalt shingle, corrugated metal, to flat build-up composition roofs. The application provides thermal insulating benefits as well as water barrier qualities. The application leaves a high quality finish with a like new restoration to any existing roof cover.

SOUND PROOFING

Does “ECOrk” Reduce Noise?

Yes, “ECOrk” is an excellent noise-reducer. It doesn’t take much to get effective soundproofing out of cork. From test conducted 3/32” (just three millimeters) of cork can block up to 10 decibels of sound.

It’s time for a quick science lesson. Sound moves in waves. In order for us to hear those sounds, all of the waves need to remain intact. When sound waves are disrupted, sounds are muffled or completely eliminated.

“ECOrk” works by breaking down sound waves within the cell walls and diffusing them.

“ECOrk” great for walls as it absorbs about 40% of the sound in the frequency range produced by the human voice. Used on walls or floors cork will deaden vibration and sound transfer by absorbing the noise, not reflecting it like a hard solid surface. “ECOrk” will effectively stop echo noise too.